CUSTOM ENGINEERING

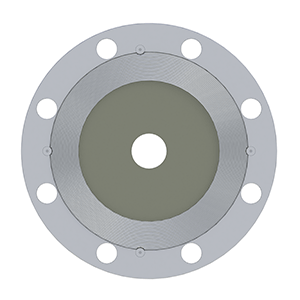

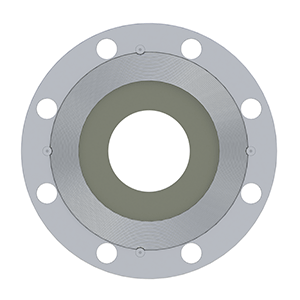

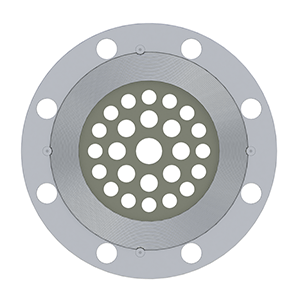

There are no off-the-shelf RocketPlates; each one is specifically engineered with a customized orifice design.

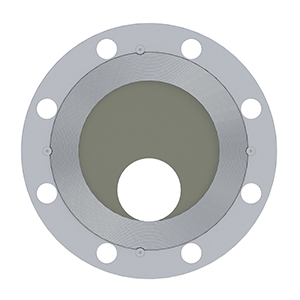

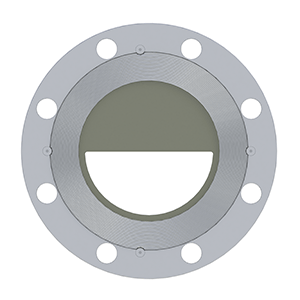

The orifice can be concentric, eccentric or segmented, and the size/geometry of the opening is based on process data and customer requirements. Our multi orifice designs may also be used as a flow conditioners, minimizing the required length of straight pipe before a flow meter or similar instrument.

CUSTOM ENGINEERING

There are no off-the-shelf RocketPlates; each one is specifically engineered with a customized orifice design.

The orifice can be concentric, eccentric or segmented, and the size/geometry of the opening is based on process data and customer requirements. Our multi orifice designs may also be used as a flow conditioners, minimizing the required length of straight pipe before a flow meter or similar instrument.

IMPECCABLE CONSTRUCTION

Each RocketPlate is cut and machined to our engineers’ exact specifications.

As metallurgy is highly dependent on application specifications, RocketPlates are available in dozens of standard and exotic materials to prevent corrosion (ex: 316SS, Hastelloy, SuperDuplex, Titanium, etc).

SUPER-HARD MATERIALS

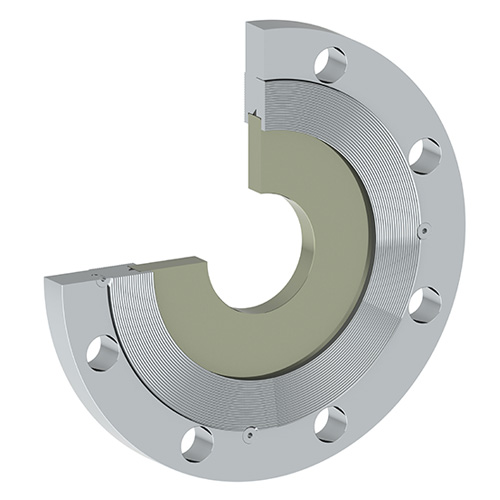

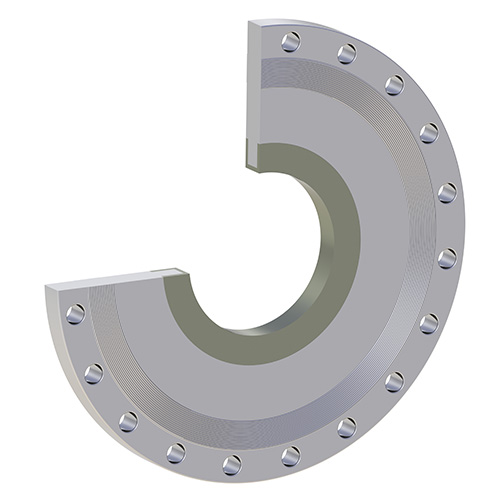

If the process media contains solids (i.e. slurry), RocketPlates are manufactured with super-hard materials for extreme abrasion resistance for the most severe services. Our 3-piece RocketPlate designs use sintered carbide discs, which are sandwiched within the plates. RocketPlates fabricated from a single piece of material (typically designed to larger orifice diameters) incorporate a wear resistant overlay to maximize service life (ex: Stellite, Tungsten carbide, Chrome carbide, etc).

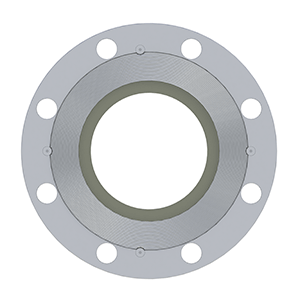

RocketPlate w/ sintered carbide

RocketPlate w/ welded hard coating

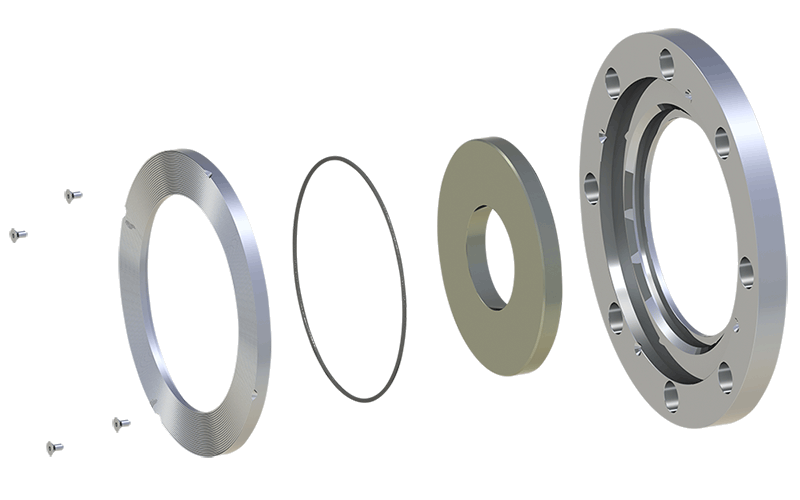

REPLACEABLE WEAR INSERTS

Our 3-piece plate design allows end users to replace the carbide disc.

This simple change-out essentially provides the customer with a new RocketPlate, as the metal housing should never experience any wear. Another advantage is that different orifice dimensions can be specified without needing to replace the entire assembly (i.e. if the flow conditions change, the plate is easily modified to suit).

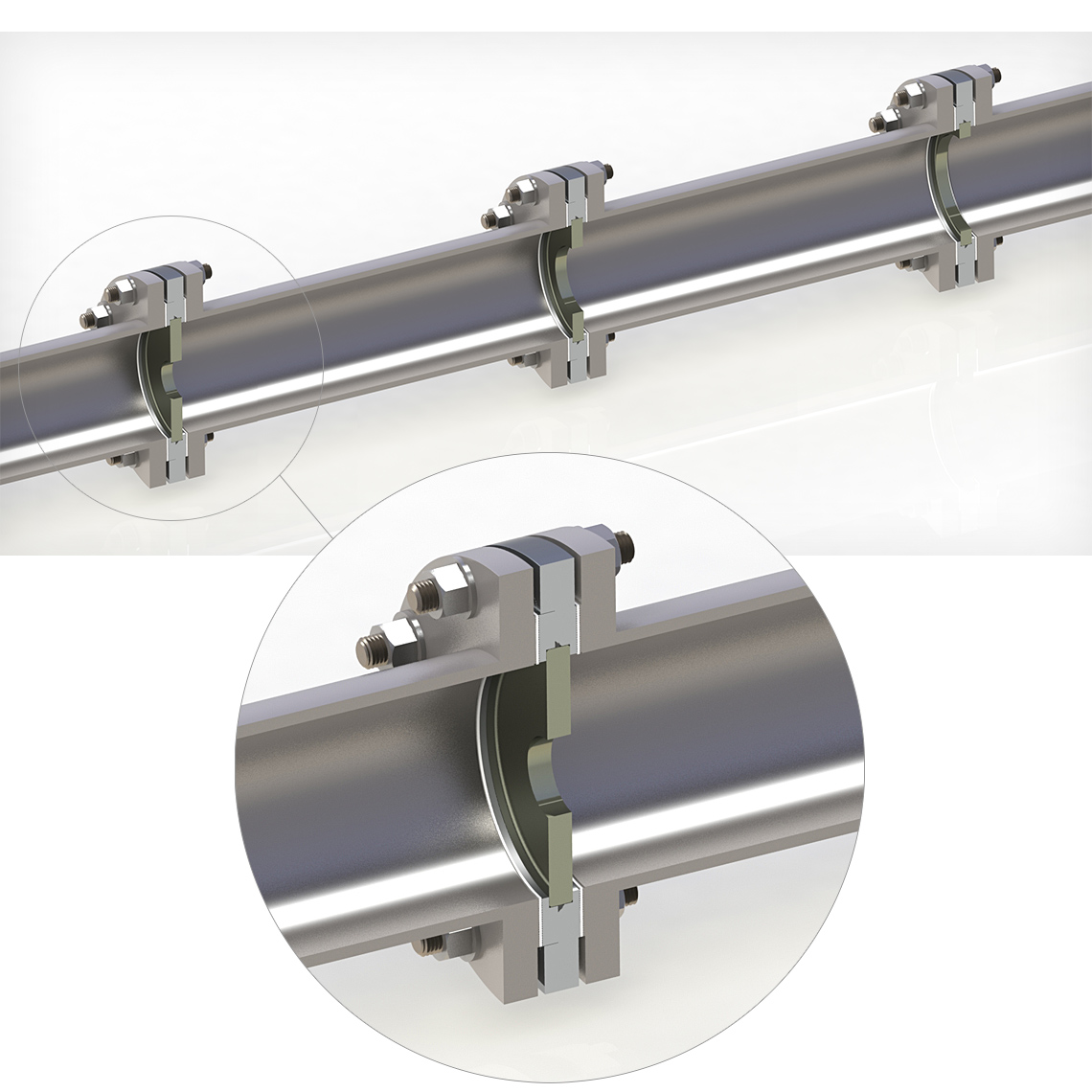

MULTI-STAGE PRESSURE REDUCTION

For applications with high pressure differential requirements, RocketPlates can be installed in series to provide a multi-stage pressure reduction. The orifice plates will share the required drop, while minimizing or eliminating noise and cavitation.

STATE OF THE ART 3D SOFTWARE

Our engineers use advanced sizing calculations, state-of-the-art flow modeling, and 3D software to optimize the performance of each orifice plate (CAD, FEA, and CFD). The result is a customized orifice plate that meets your exact application requirements.